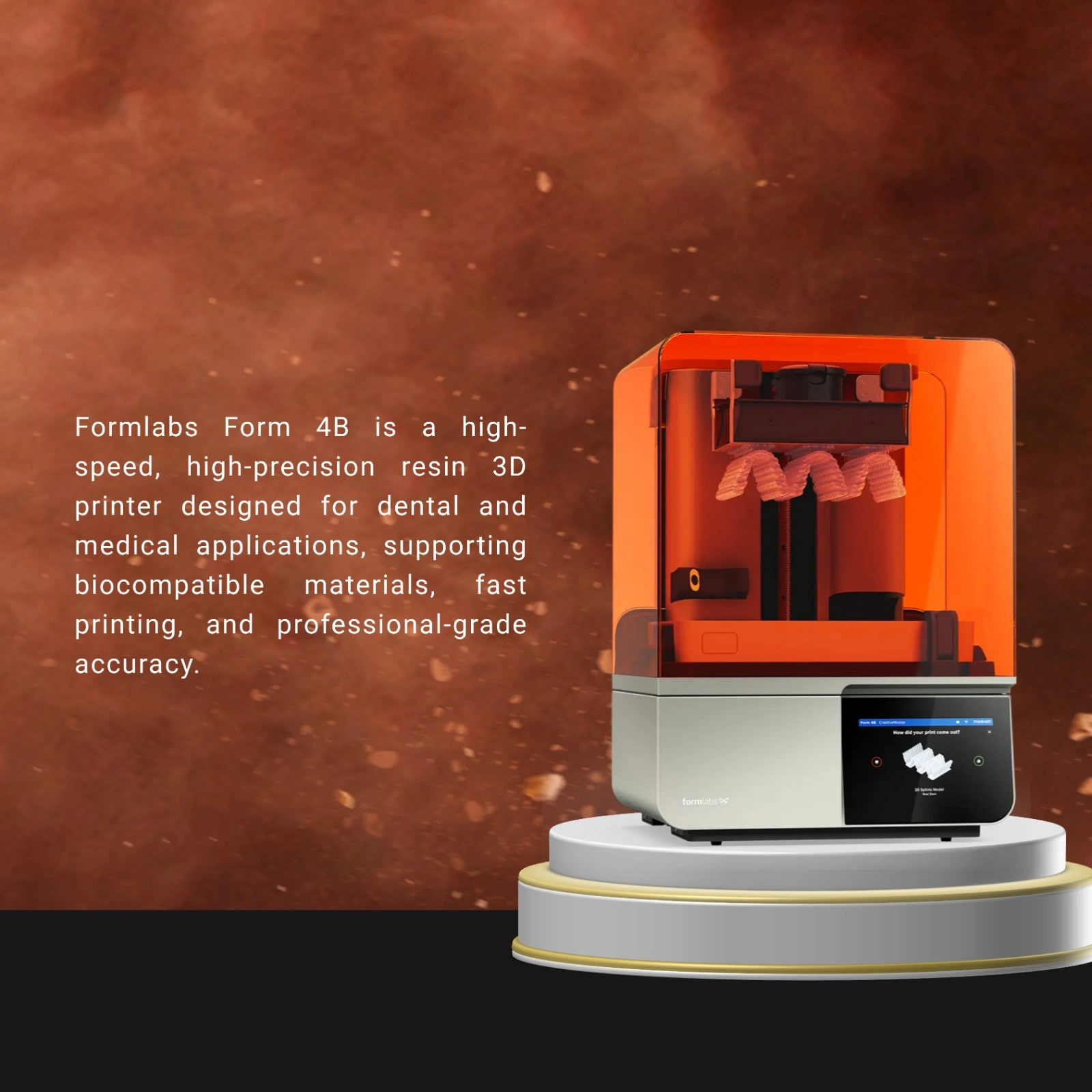

FORMLABS: High Accuracy. Low Cost. Zero Compromise

Formlabs is a leading professional 3D printing brand from the USA, backed by a world-class R & D team dedicated to industryspecific innovation. Global leaders like NASA, Tesla, Marvels, Ford, and Microsoft trust Formlabs for highprecision prototyping and dependable production.

What makes formlabs stand out?

Why only Formlabs???…

Because precision, reliability, and consistency aren’t optional-they’re essential.

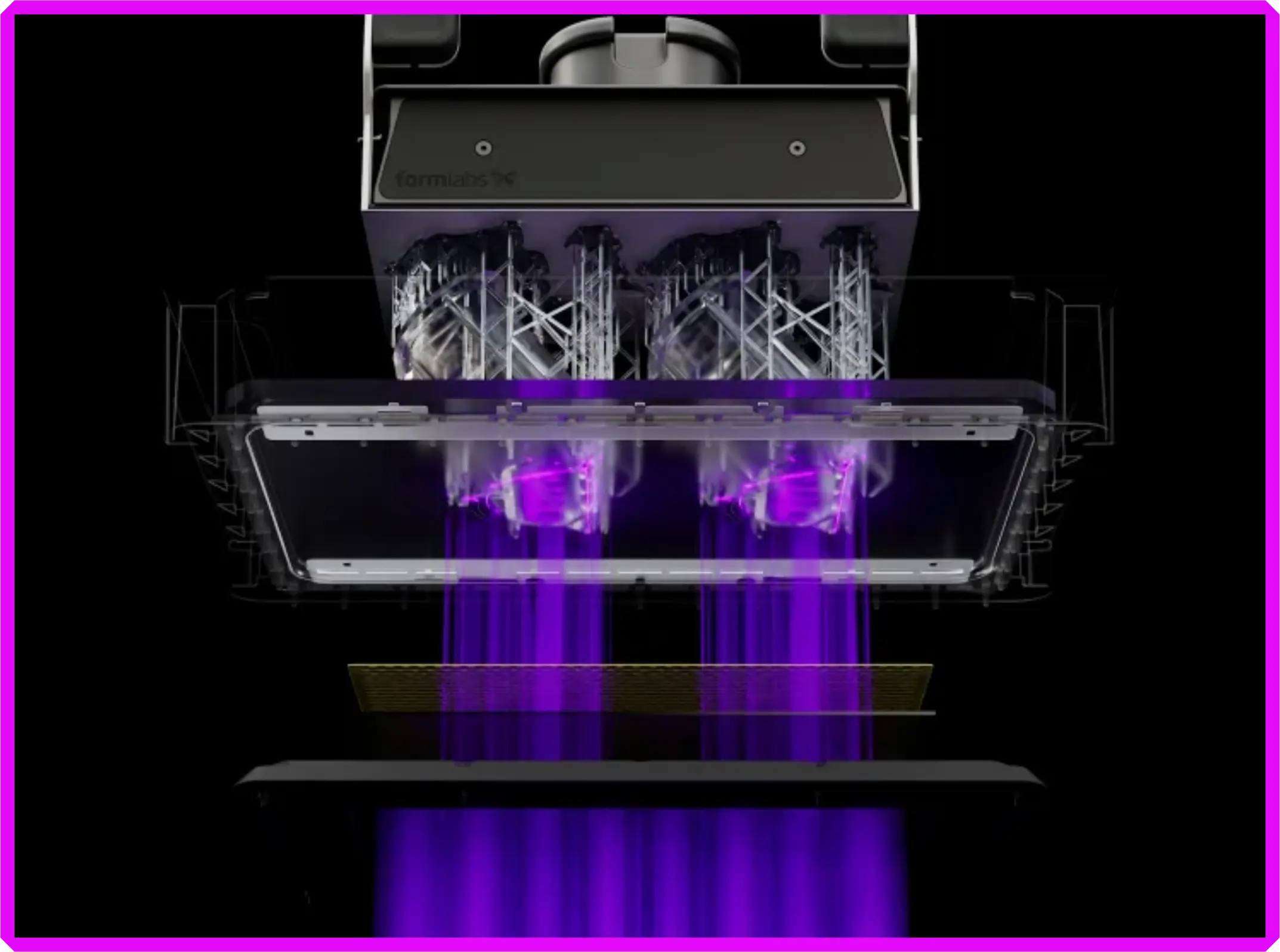

Low Force Display: Engineered

for Speed, High-Accuracy with

extraordinary results.

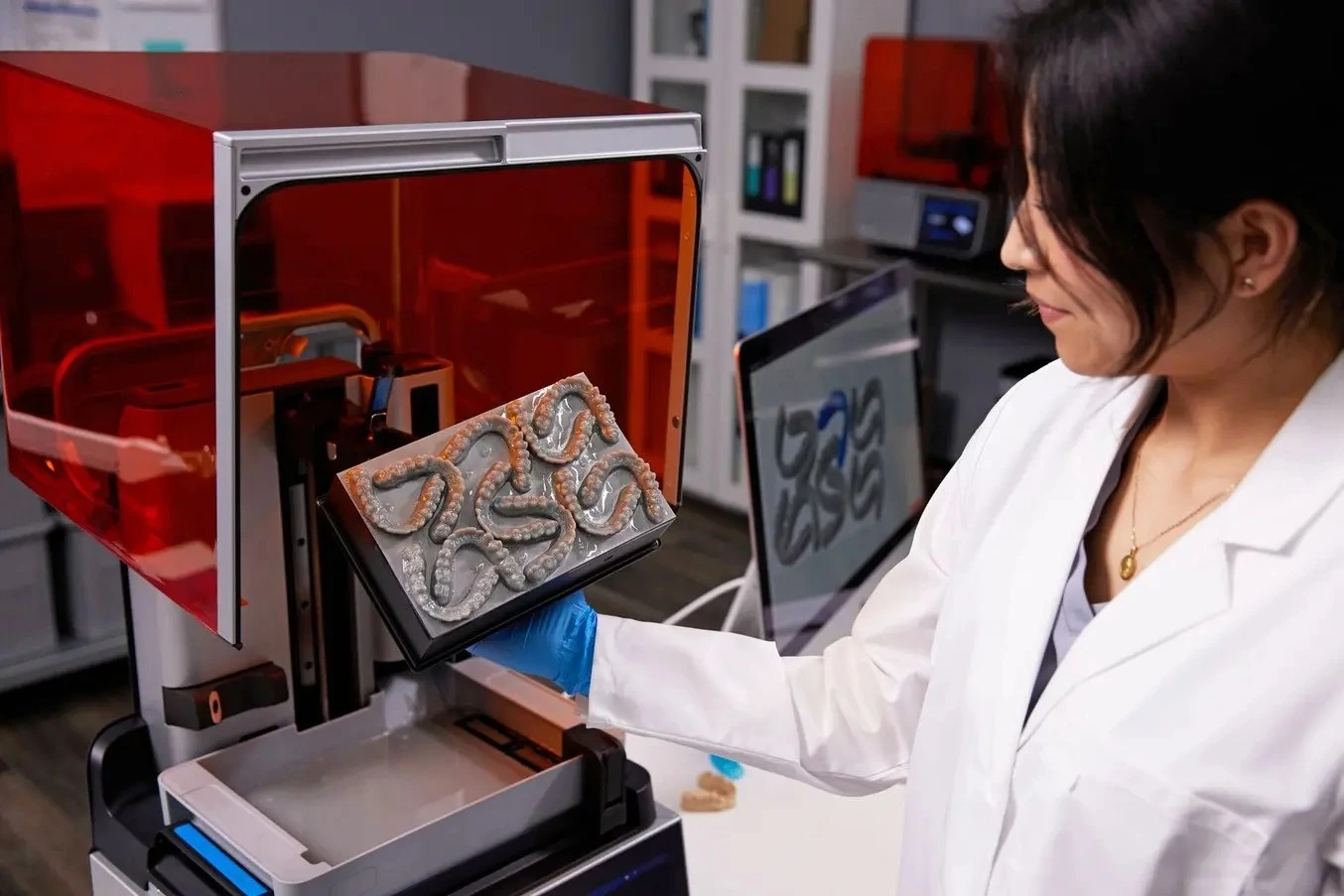

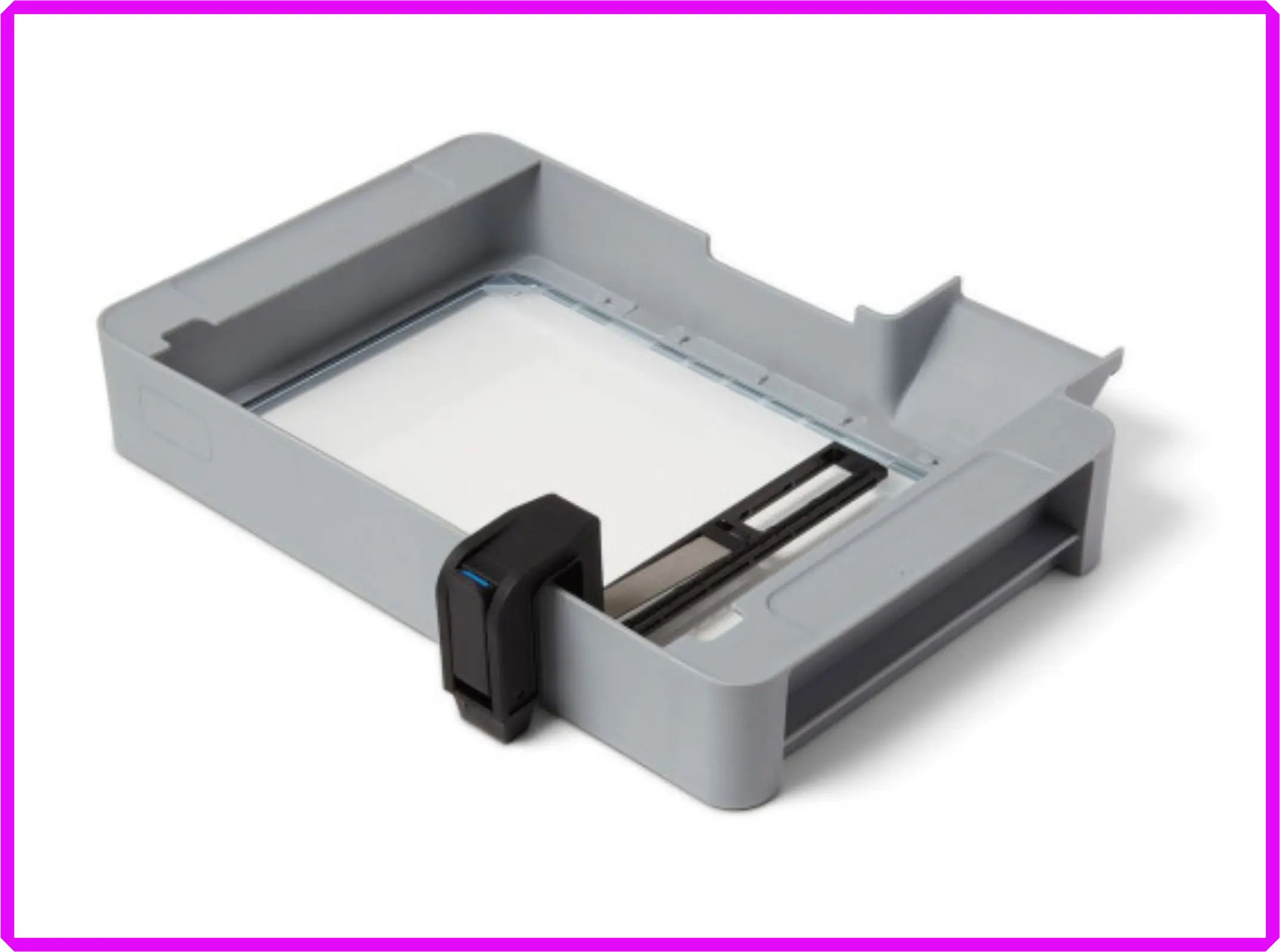

Build Platform Flex: Simplifying

Part Removal with a Quick, No Tools,

No Damage, Just a Gentle

Bend Clean Flex.

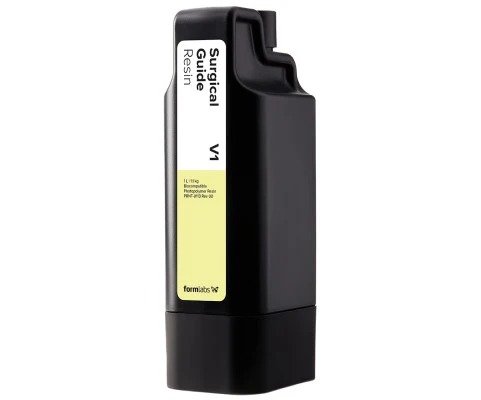

Resin Mixer: Precision mixing with

intelligent debris detection.

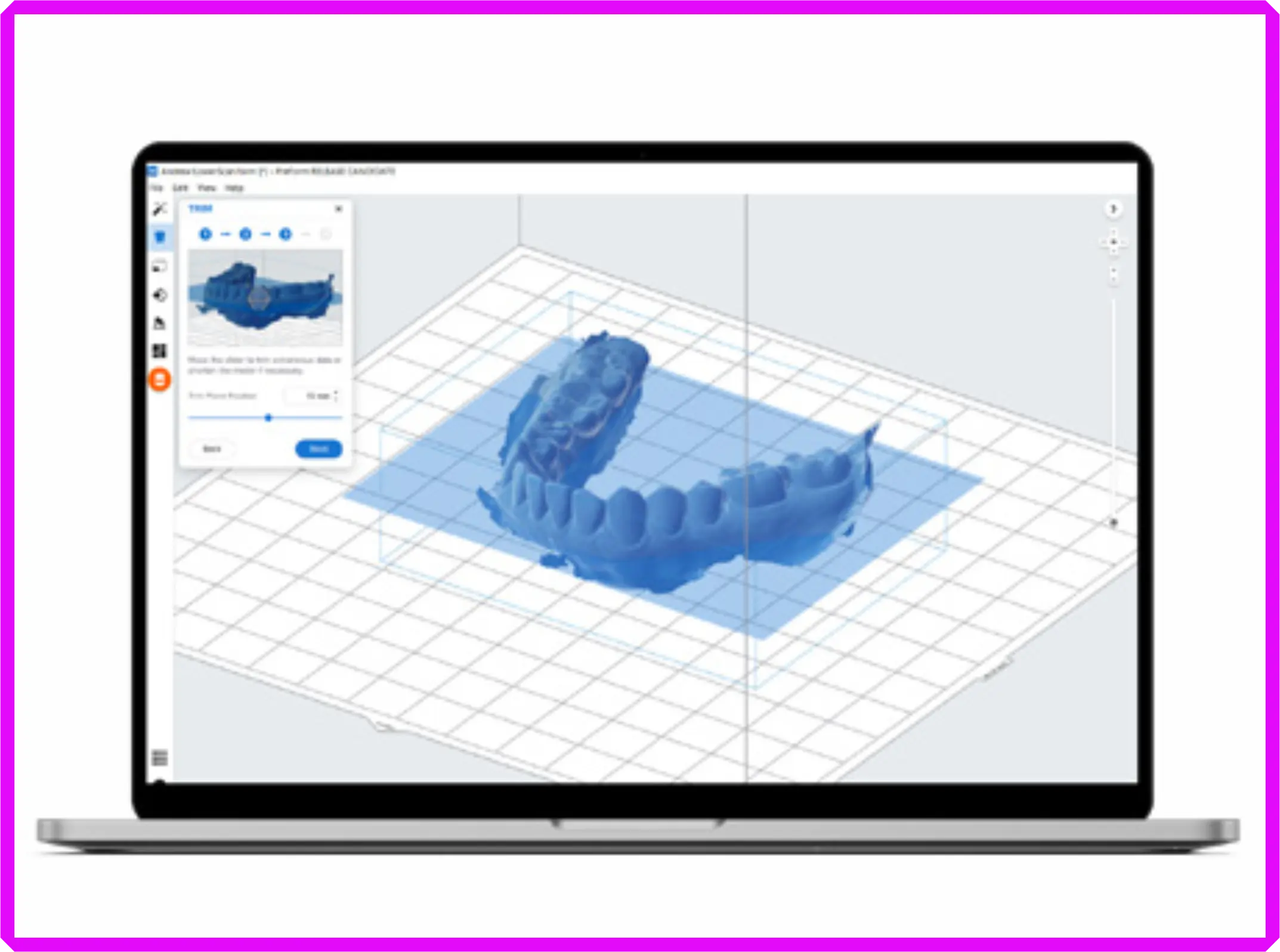

Preform AI : Let PreForm AI handle

the prep-so you can focus

on creation.

Open Material Mode

A game-changer for Formlabs:

the once closed printers open up.

Works with third-party resins

Third Party Resin

No longer restricted to

Formlabs proprietary materials

open material mode allows you

to pour resin into trays and print.

This provides more flexibility for

materials selection.

Open Material Mode: Perfect for experimentation,

specialty resins, and custom workflows-your

printer, your rules

One Printer. Every Material. All Applications- Printed at Breakneck Speed

One Ecosystem. Endless Possibilities…

Orthodontic Applications

Models for Diagnostics and Thermoformingn Appliances

Models in Record Time for Diagnosis or Aligner Production

Indirect Bonding Trays

Accurate Bonding That’s Easier to Plan and Use

Occlusal Splints and Guards

For Long-Lasting Rigid and Flexible Appliances

Restorative Applications

Wax-Up Models

Your Digital Design With a Smoother Surface Finish

Restorative Models

Soft and Rigid Components for Better Prosthetic Planning

Restorations

State-of-the-Art Ceramic-Filled Restorations