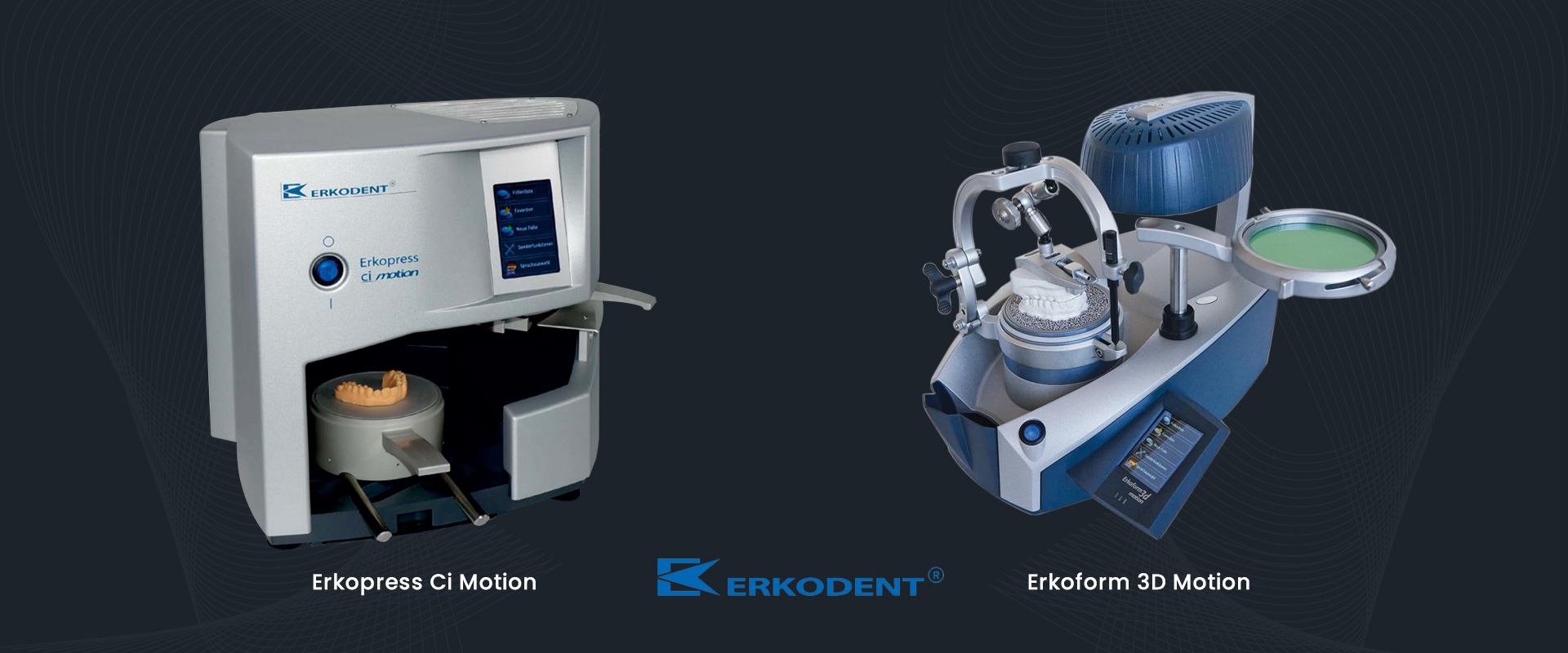

Erkodent

Erkodent thermoforming machine comes in 2 variants: Erkoform 3D Motion (vacuum forming) & Erkopress Ci Motion (pressure moulding). You can choose the model as per your need & use it with the wide variety of erkodent materials & 3rd party materials for every application.

The Erkopress ci motion

The latest advancement in the popular Erkopress line of countertop thermoforming units from ERKODENT®, streamlines the fabrication process for increased efficiency. Much like its predecessor, the Erkopress 300 Tp-ci™, this thermoforming unit is designed to use an integrated air compressor to fabricate bite plates, fluoride and bleaching trays, sports mouthguards, orthodontic splints and more, with precision and ease.

While featuring the familiar touchless temperature sensor and touch panel display with preprogrammed settings, the Erkopress ci motion improves upon earlier models by automating the thermoforming process: After the foil is heated to the appropriate temperature, the foil is automatically placed onto the model, starting the thermoforming process.

Erkopress 300 Tp-ci is a trademark of ERKODENT Erich Kopp. ERKODENT is a registered trademark of ERKODENT Erich Kopp.

Features

- Touchless temperature sensor

- No preheat time required

- Touch panel display with preprogrammed settings

- Automated thermoforming process

- Integrated air compressor with reserve pressure chamber

- Accepts foil thicknesses from 0 to 5.5 mm

Technical Specifications

- Height: 32 cm (12.6 inches)

- Width: 33 cm (13 inches)

- Depth: 51 cm (20.08 inches)

- Weight: 22.9 kg (50.48 pounds)

- Reserve Pressure: 7 bar

- Watts: 480

- Volts: 230 (or 110)

- Hertz: 50

- Noise Level (Compressor): < 74 db(A)

The Erkoform 3D™ Motion

Is the first Erkodent thermoforming unit to feature an automated thermoforming process. It is designed to fabricate various dental appliances such as bite splints, nightguards, retainers, fluoride and bleaching trays, sports mouthguards, and orthodontic appliances. It uses a vacuum technique to thermoform and imprint the opposing bite for optimum fit. This unit includes a touchless temperature control, reserve vacuum, preprogrammed settings, and a touchpanel screen for simple program operation. No external compressed air supply is required.

The machine’s function and technical data is equivalent to the Erkoform 3D, save for an improved touchpanel and operating concept. The automatic thermoforming process makes it unnecessary to manually move the hot foil from the heating unit to the model, and to thermoform. Simply position the model and initiate the heating cycle, effectively increasing productivity and reducing costs.

Purchase of the Erkoform 3D Motion includes a material samples kit, step-by-step technique manual, and an easy-to-follow technique DVD.

Features

- No external compressed air supply required

- Easy operation; Erkodent foil heating temperatures and cooling times preprogrammed; custom programs easily added

- Touchless temperature sensor for accurate determination of the actual thermoforming material temperature

- No preheating time

- Sudden vacuum, built up before thermoforming process

- More space for higher models

- Perpendicular pre-stretching and forming produces results of even foil thicknesses

- Completely accessible model during the heating process

- Practical one-hand foil fixation for foil thicknesses ranging from 0 to 5 mm

- Complete with granules and materials trial pack

Accessories

Occluform-3® attachment: may be integrated with Erkoform 3D and Erkoform 3 units for imprinting the opposing bite. Attachment sold separately.