DWX-52DCi Plus

5-Axis DRY Dental Milling Machine with Disk Changer

Advantages of Choosing the DWX-52DCi Plus

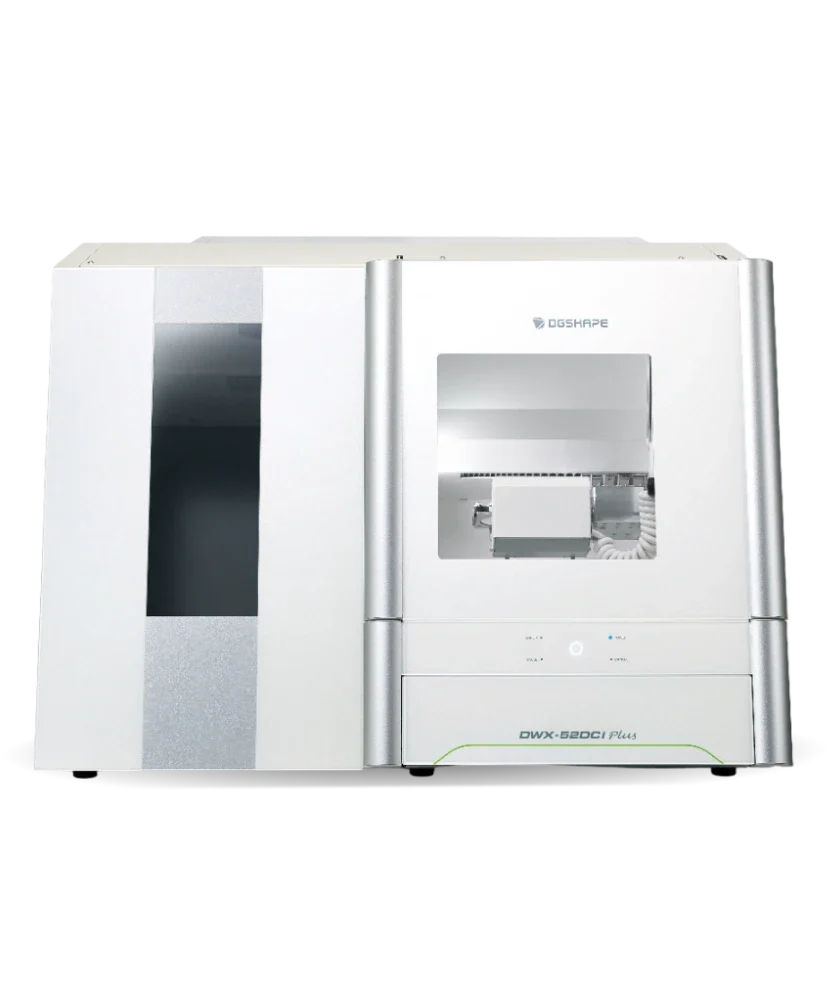

With the DWX-52DCi Plus, our 5-axis dental milling machine, you can boost your productivity even outside of regular hours or when you’re away: this dry dental milling machine continues to operate seamlessly without the need for anyone nearby.

With its open CAD/CAM system, material flexibility and the DGSHAPE Insight software for visualizing ROI and productivity, the DWX-52DCi provides anexceptionally powerful, efficient, affordable solution for your dental laboratory or clinic.

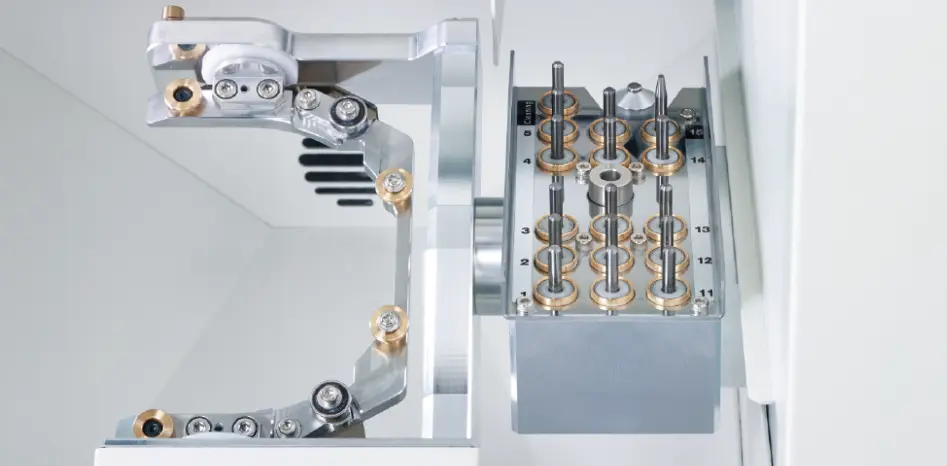

Thanks to the 6-slot Automatic Disc Changer, 15-station Automatic Tool Changer, it offers the ultimate in 24-hour productivity for users of all skill levels.

DWX-52DCi Plus

Millable Materials

Discover the Variety of Materials You Can Mill with Your New 52DCi Plus.

Millable Applications

Discover the Range of Applications You Can Create with Your 52DCi Plus.

Whether you’re crafting dental crowns, bridges, or custom implants, this advanced technology ensures exceptional quality and consistency in every piece.

With the 52DCi Plus, you can explore a wide range of dental applications, all produced with the highest standards of accuracy and detail.

Inlay

Onlay

Overlay

Bridge

Crown

Veneer

Toronto Bridge

Copings

Implant Bar

Surgical Guide

Occlusal Splint

& Bites

Removable Dental

Prostheses

Highlights

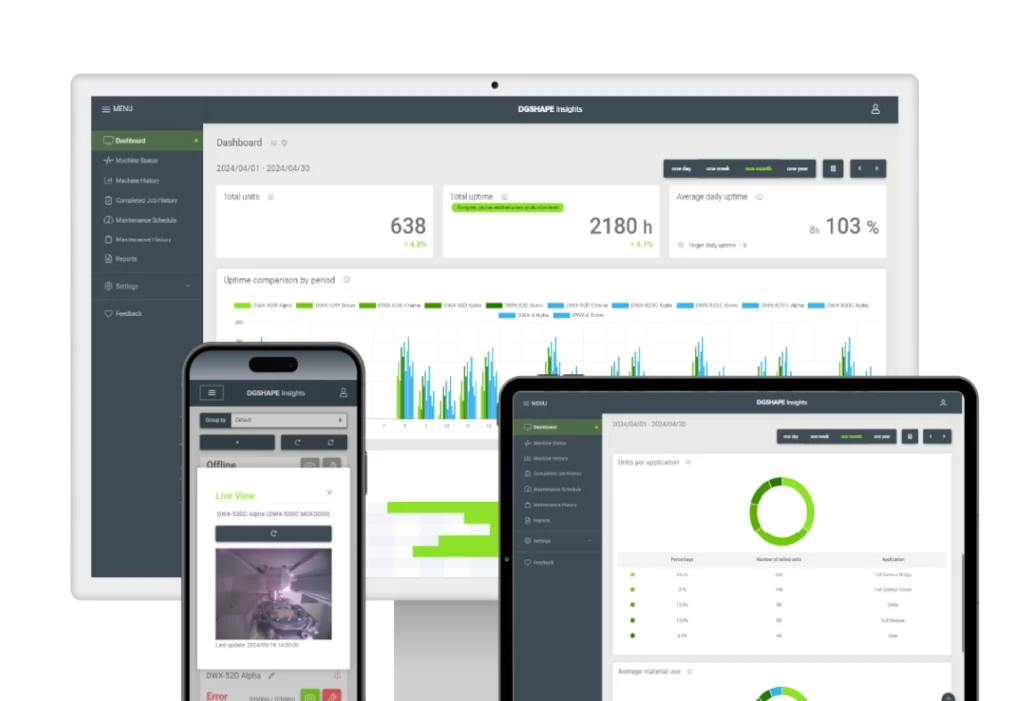

DG SHAPE CLOUD

Fully leverage your experience with DGSHAPE through DGSHAPE CLOUD, an advanced cloud service provided by DGSHAPE.

Accessible via your DGSHAPE Account, it grants you access to Insights, a tool for remotely monitoring your CAD/CAM milling devices and supporting your business.

Technical information