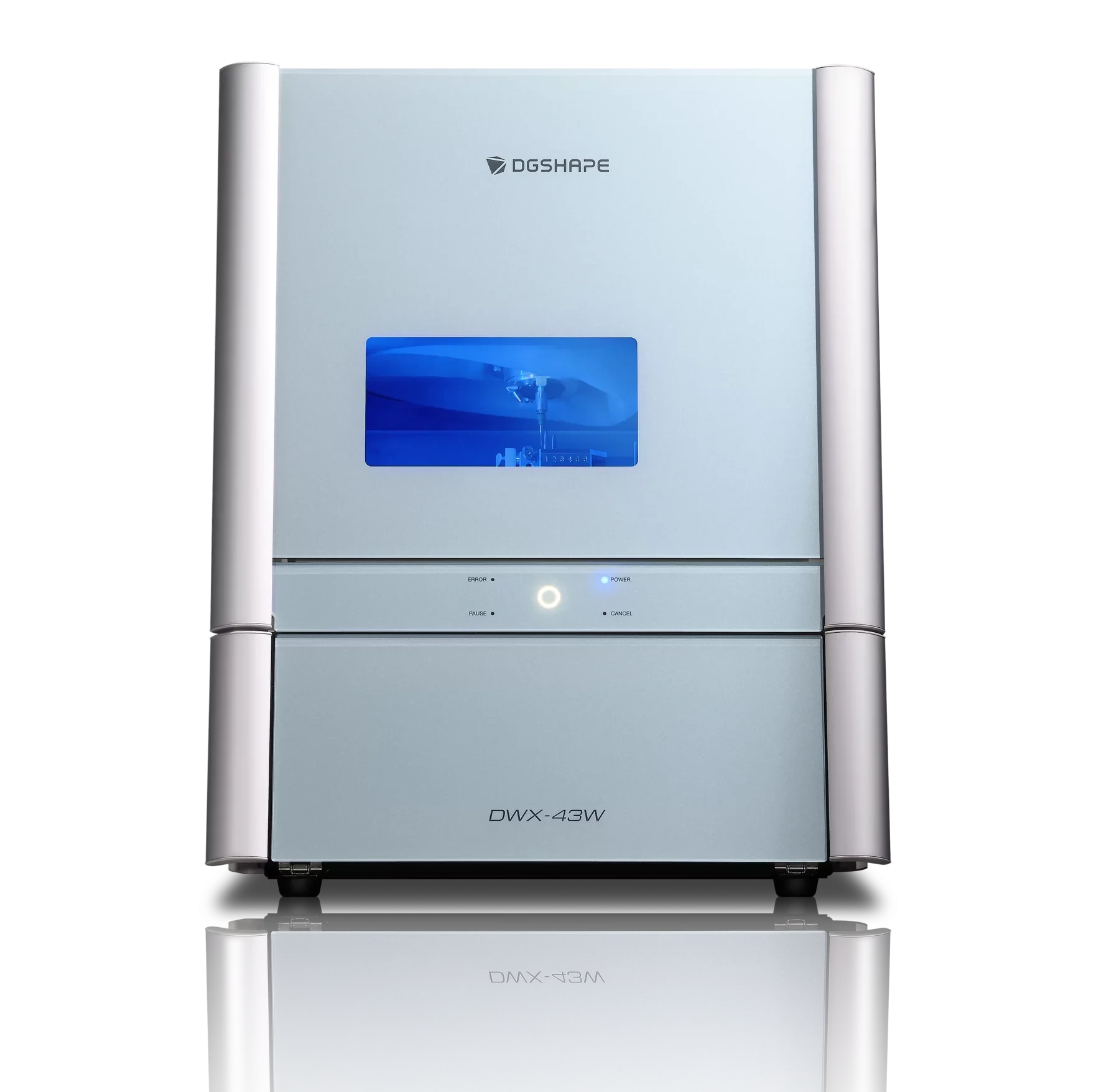

DWX-43W

Wet Solution 4-Axis Dental Milling Machine with DGSHAPE CAM Software Included

Advantages of Choosing the DWX-43W

Boost your productivity and precision with the DWX-43W, the new versatile wet milling solution from industry leader DGSHAPE.

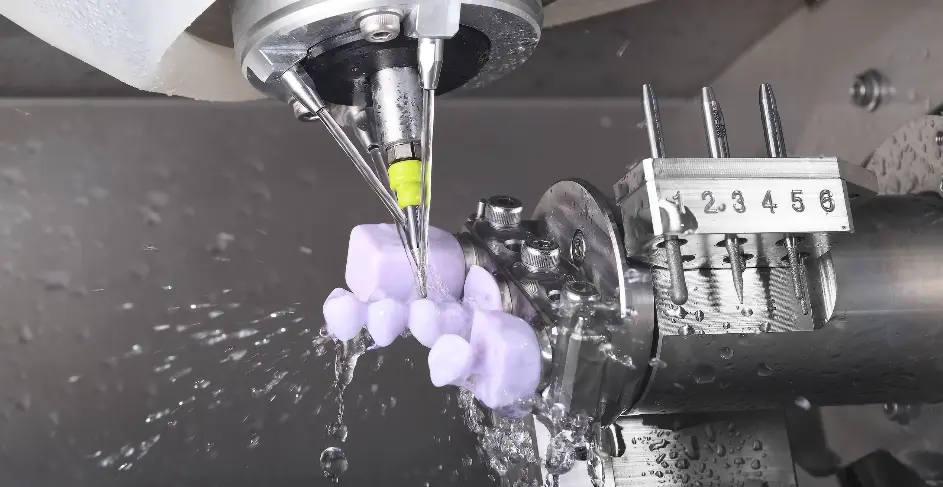

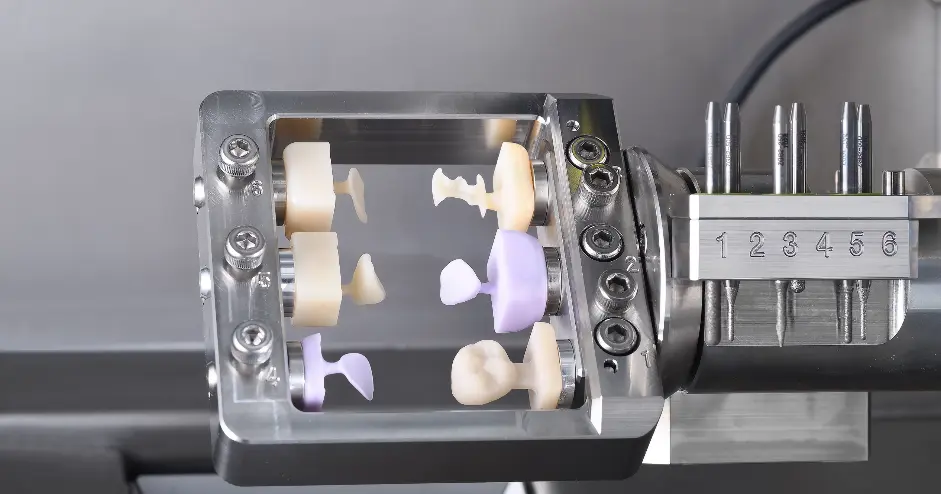

The DWX-43W can simultaneously mill up to six pin-type blocks with unparalleled accuracy.

Compatible with a wide range of materials, including sintered zirconia, glass ceramics, hybrid ceramics, PEEK, composite resins, PMMA, and titanium alloy*, it’s designed to meet all your in-house production needs.

From crowns and veneers to custom titanium abutments (with optional attachments), the DWX-43W ensures consistent, high-quality results while streamlining workflows with automated maintenance and user-friendly software.

Experience faster, smarter, and more versatile milling with the DWX-43W – the perfect blend of precision, performance, and affordability.

*Optional attachment required for titanium alloy milling.

DWX-43W

Millable Material

Discover the Variety of Materials You Can Mill with Your New DWX-43W

Discover the Range of Applications You Can Create with Your DWX-43W.

Whether you’re crafting dental crowns, bridges, or custom abutments, this advanced technology ensures exceptional quality and consistency in every piece.

With the DWX-43W, you can explore a wide range of dental applications, all produced with the highest standards of accuracy and detail.

Inlay

Onlay

Overlay

Crown

Bridge

Veneer

Abutments

DG SSHAPE CAM

for DWX-43W

for DWX-43W

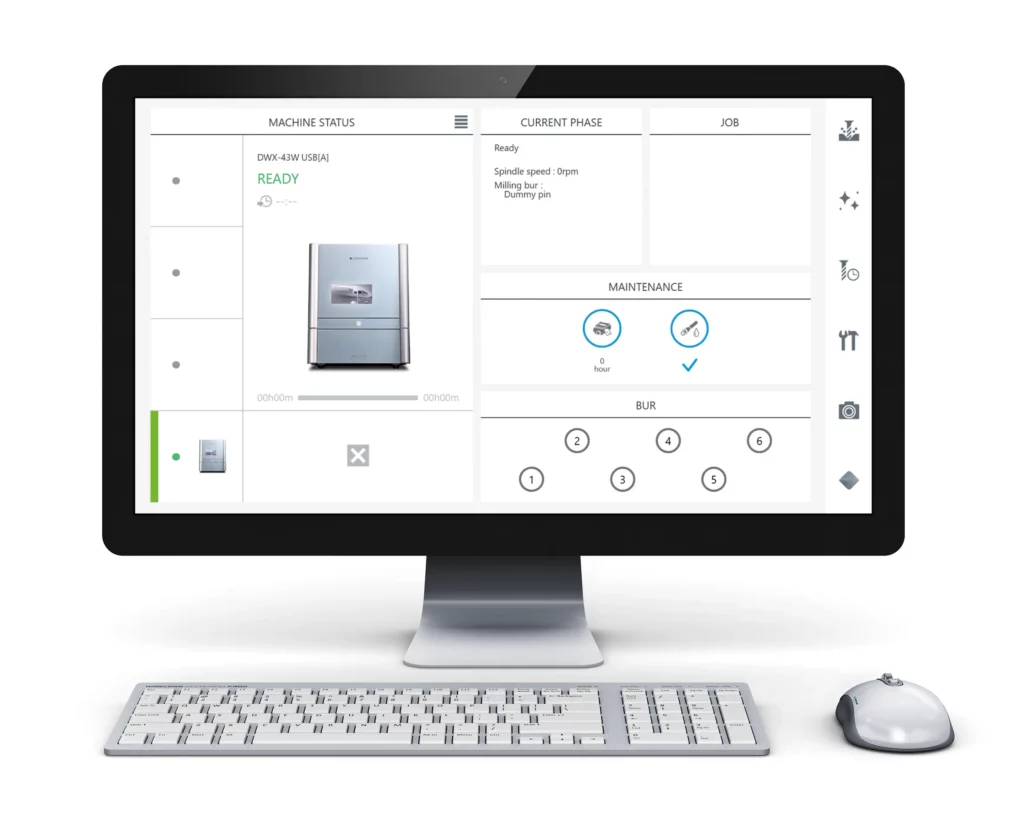

Optimize Your Workflow with Bundled DGSHAPE CAM for DWX-43W.

Included DGSHAPE CAM Software enables you to select either High-Quality (Standard) or Fast Strategy production according to your needs.

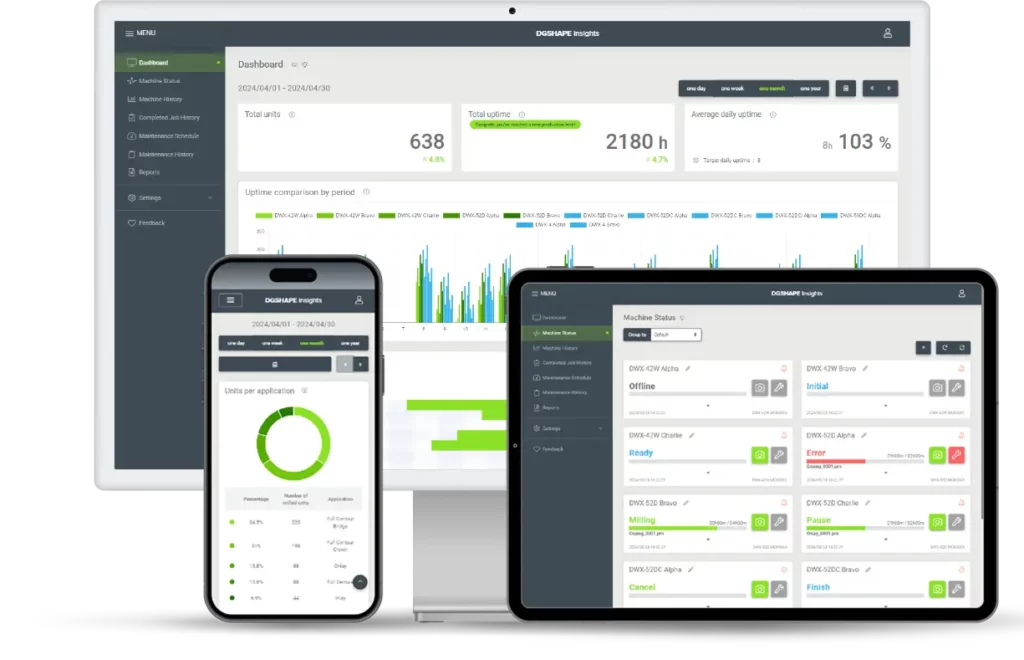

In addition, DGSHAPE CAM is fully integrated with DGSHAPE Insights, enabling DGSHAPE Insights to display more detailed information, such as the number of outputs and materials used, and to provide deeper insights to improve your operations efficiency.

DGSHAPE CLOUD

Fully leverage your experience with DGSHAPE through DGSHAPE CLOUD, an advanced cloud service provided by DGSHAPE.

Accessible via your DGSHAPE Account, it grants you access to Insights, a tool for remotely monitoring your CAD/CAM milling devices and supporting your business.