DWX-52Di Plus

Entry Level 5-Axis DRY

Dental Milling Machine.

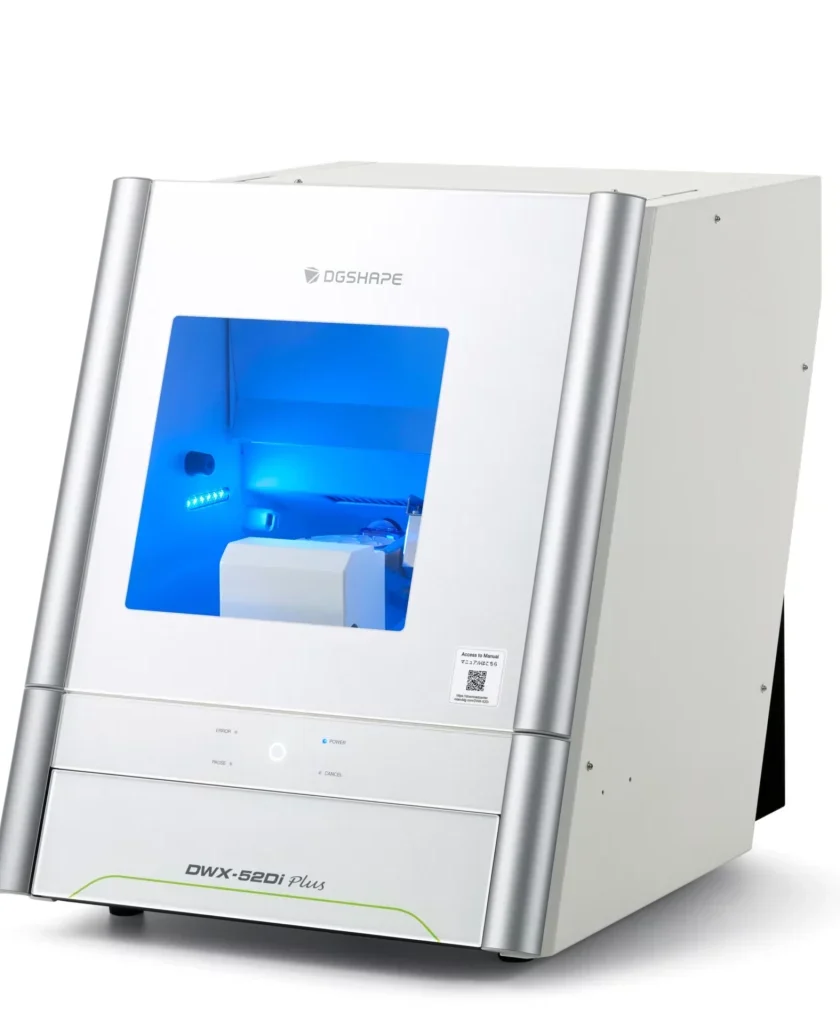

PREMIUM QUALITY WITHOUT THE PREMIUM PRICE

Advantages of Choosing the DWX-52Di Plus

Save time and costs with the 5-Axis DWX-52Di Plus dental milling machine and its entry-level price!

Cost-effective with high quality, the DWX-52Di Plus’s 5-axis milling technology is a precise and efficient dental restoration solution, allowing users to produce a wide range of restorations, including crowns, copings, bridges, inlays, onlays, veneers, abutments, implant bars, and screw-retained crowns.

Its upgraded user-replaceable spindle and C-type clamp are also compatible with disc- and pin-type materials, enhancing the machine’s efficiency and versatility.

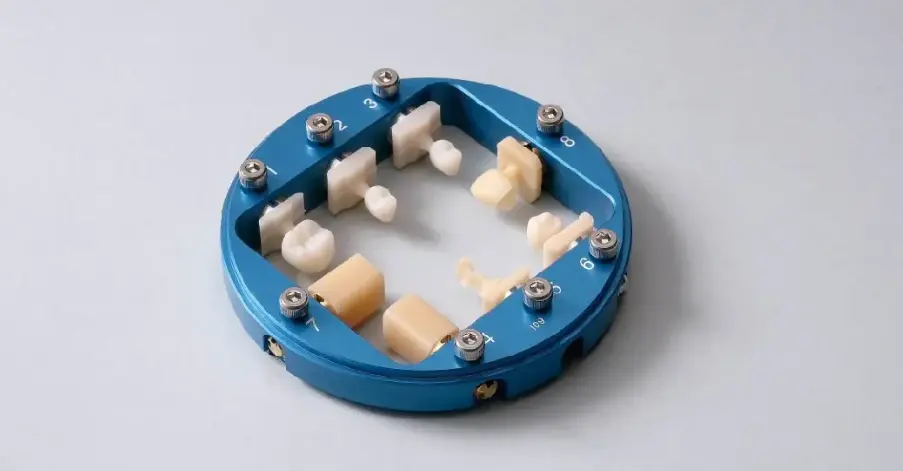

Millable Material

Discover the Variety of Materials You Can Mill with Your New DWX-52Di Plus.

Millable Applications

Discover the Range of Applications

You Can Create with Your DWX-52Di Plus.

Whether you’re crafting dental crowns, bridges, or custom implants, this advanced technology ensures exceptional quality and consistency in every piece.

With the DWX-52Di Plus, you can explore a wide range of dental applications, all produced with the highest standards of accuracy and detail.

Toronto Bridge

Copings

Implant Bar

Highlights

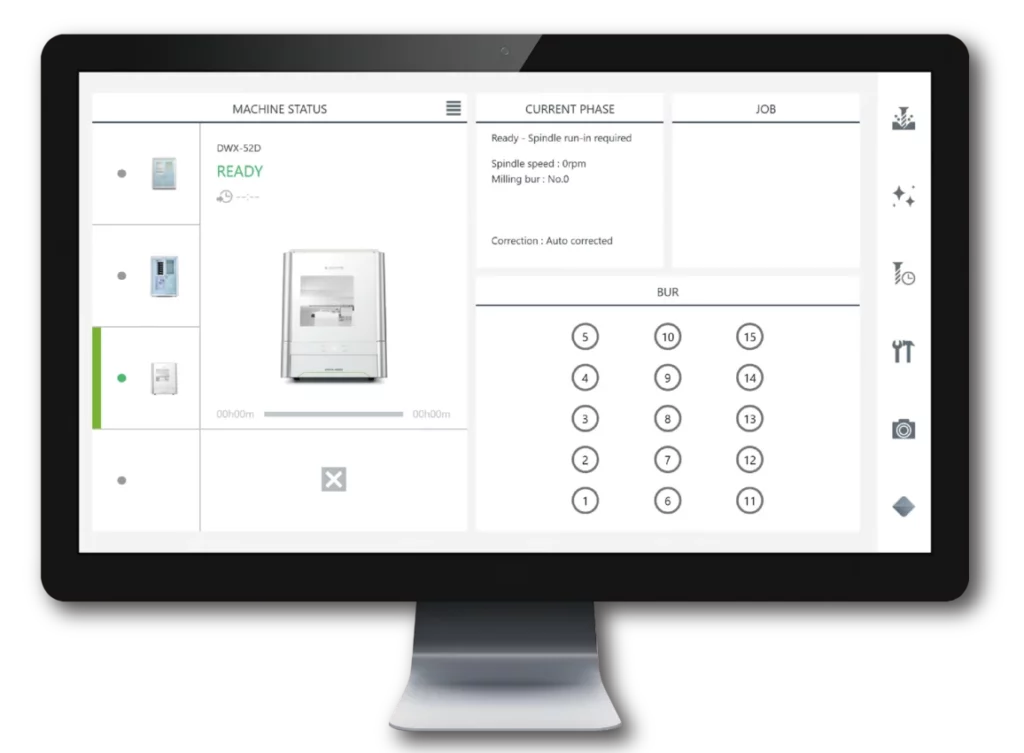

VPanel for DWX

User- and Eco-Friendly Operations

VPanel for DWX seamlessly provides maintenance oversight and output performance control. The Intelligent Tool Control automatically swaps out tools when they have reached their user-defined lifespan.

The DWX-52Di Plus is an energy-efficient, environmentally friendly dental mill that minimizes power consumption while delivering top performance.

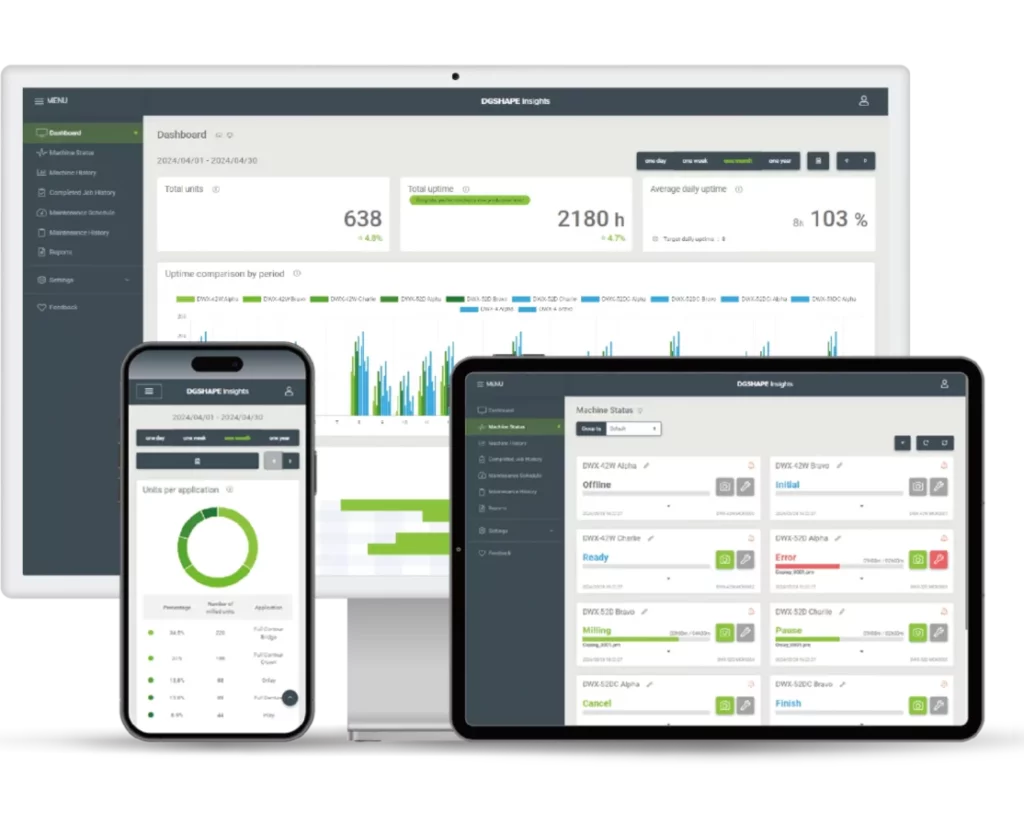

DGSHAPE CLOUD

Stay Tuned-In to Tune-Up with DGSHAPE CLOUD

DGSHAPE offers remote monitoring for all DWX devices through its management software, available in DGSHAPE CLOUD. You can monitor machine status anytime, anywhere, while accessing valuable data, maintenance support, and actionable insights for optimal operations.

Technical information